Problem

Wawa, a prominent convenience store chain, faced significant challenges in managing food waste and inventory. Due to short expiry deadlines of their fresh items, reliance on past data and employee guesstimations led to high spoilage and overproduction. This inefficient inventory management also resulted in increased carbon emissions and resource wastage, affecting both the environment and Wawa’s profitability. The inaccuracies in forecasting and excess food preparation undermined their sustainability goals and operational efficiency, highlighting the urgent need for an innovative solution.

Solution

Techolution developed an AI-powered solution to tackle Wawa’s inventory management and food waste challenges - A Real-time Inventory Monitoring System. This used advanced AI and computer vision technologies to monitor inventory levels continuously, employing cameras and AI models for precise tracking. Predictive algorithms optimized production schedules by forecasting sales and spoilage, while a replenishment recommendation engine provided real-time guidance to kitchen staff for efficient food preparation. The system also integrated edge devices, cloud services and machine learning algorithms for enhanced forecasting accuracy.

Impact

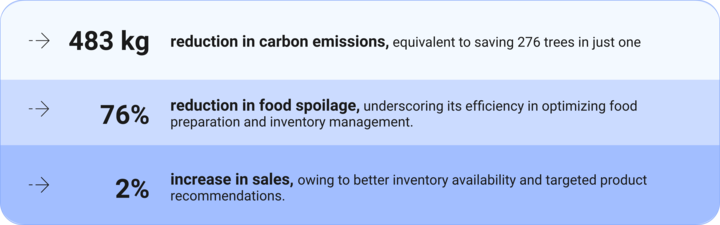

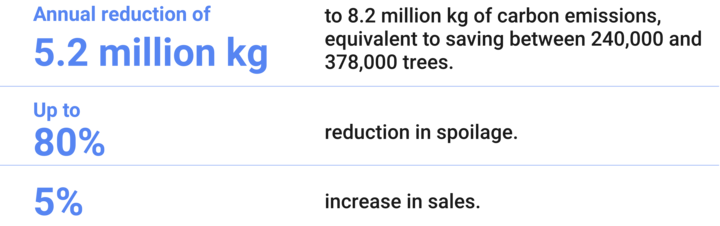

This AI-powered solution achieved impressive results during a 28-day pilot, reducing food spoilage by 76%, improving inventory management, and cutting carbon emissions by 483 kg per store (saving 276 trees). It also increased sales by 2% through better inventory and recommendations. Projected annual reductions across 900 stores include 5.2 to 8.2 million kg of carbon emissions (240,000 to 378,000 trees saved) and potential annual savings of $6.6 to $12.8 million, with an 80% reduction in spoilage.

Wawa, a renowned convenience store chain known for its fresh, fast-consumable breakfast and lunch items, faced a significant challenge a few years ago. While their extensive network of stores emphasized the freshness of their items, it also meant dealing with tight expiry deadlines – ranging from a few minutes to an hour. This added to a severe and widely prevalent issue in the food retail industry : food wastage.

Every year, 40 million tons of food are discarded in the United States, which equates to cutting down 7.8 billion trees annually. A huge amount of food is wasted from grab-and-go food warmers due to food preparation being largely based on past data and employee guesstimation. The outcome? Overproduction, spoilage, and massive environmental damage.

Tackling Food Waste With AI Innovation

Wawa recognized the need for an innovative approach to manage their inventory and optimize food production to solve the issue at hand. That’s when they turned to Techolution to address their inefficiencies with the help of our expertise in AI and computer vision. The goal was clear:

- Reduce food waste

- Optimize inventory management

- Maintain the freshness of food that Wawa customers love

Techolution proposed a Real-time Inventory Monitoring System, a sophisticated integration of AI technologies designed to continuously monitor the consumption and replenishment of items in Wawa’s warmers throughout the day. This way each item could be accurately tracked and replenished in a timely manner. The system didn’t just track inventory; it made real-time recommendations to the kitchen on how much of each item to prepare, improving decision-making and adapting to fluctuations in customer footfall and minimizing waste.

Real-time Inventory Monitoring

The implementation of this system visibly brought about a revolution. Techolution equipped Wawa’s stores with cameras integrated with AI models, capable of continuously monitoring inventory levels with astonishing accuracy. This computer vision AI system could identify items based on shape, color, and even text.

The real-time item tracking provided precise data on inventory status at any moment. But the next level of this solution was in AI-enabled sales and spoilage forecasting. Using advanced algorithms, the system could predict sales patterns and potential spoilage, optimizing the production schedules accordingly. The replenishment recommendation engine, a crucial component, provided minute-by-minute guidance to kitchen staff, ensuring they knew exactly how much of each item to prepare to meet demand without overproducing.

The technology behind this system was robust. We used edge devices to handle on-site processing and leveraged Cloud services that were instrumental in classifying food items and providing accurate inventory updates in real time. Our solution incorporated no-code data annotation and model retraining, ensuring the system’s accuracy and continuous improvement. Despite our confidence in the solution, it was important to conduct a trial run.

From Pilot Success To Full-Scale Implementation

We first conducted a 28-day pilot at a single Wawa store before going full-scale, and the results were astounding. The system achieved:

The success of the pilot projected substantial benefits, encouraging Wawa to scale the AI solution that Techolution offered across its stores. With an estimated annual savings of $6.6 million to $12.8 million for 900 stores, Wawa was on track to achieve significant financial gains. The potential benefits included:

Our AI solution didn’t just optimize processes; it also empowered Wawa’s staff. Previously, new kitchen employees had to rely on intuition and experience to determine how much food to prepare. Now, with the AI system providing precise recommendations, new staff could confidently produce the right quantities of each item, reducing training time and enhancing overall efficiency. But the transformation didn’t end there.

Heading toward a Sustainable Future with AI in Retail

The AI-driven solution positioned Wawa as a leader in sustainable retail practices, demonstrating how technology can deliver both economic and environmental benefits. This innovative solution not only addressed Wawa’s immediate challenges but also paved the way for broader adoption of AI technologies in the retail industry.

Wawa’s journey with Techolution sheds light on the scope of AI-led transformation in retail. By addressing critical challenges with innovative solutions, Techolution enabled Wawa to achieve remarkable profitability and sustainability goals. Wawa’s successful adoption of AI serves as an inspiration to retailers to embrace artificial intelligence for a greener and more efficient future.